search

What Are You Looking For?

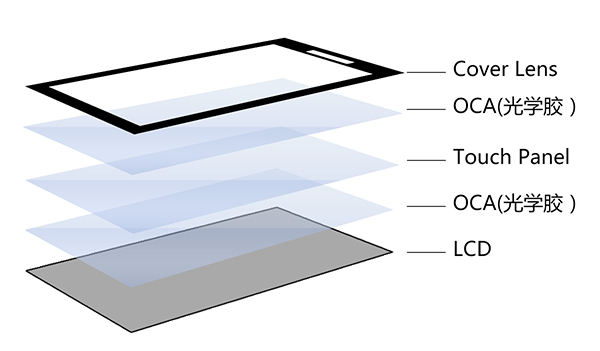

Taking an LCD screen with a capacitive touch screen as an example, the overall structure of the display module can be roughly divided into 3 parts. From top to bottom, they are the protective cover glass, the touch screen, and the display screen. The way to glue these 3 parts together is bonding. There are two methods: Optical bonding and Air Bonding.

Optical Bonding

Definition: Optical Bonding refers to the technology that uses transparent optical glue, liquid OCA glue, OCA glue or SCA glue) to completely bond the touch screen and display screen together seamlessly to form a whole screen. The bonding strength is greatly increased.

Advantages:

Disadvantages:

Air Bonding

Definition: it is also known as Double-tape adhesive bonding, that is, simply sticking the touch screen and the four sides of the display screen with double-sided tape. The middle of the two screens is empty and has air.

Advantages:

Disadvantages:

For different type touch screen, generally it is air bonding for RTP touch( Resitive touch panel) and LCD screen. Either optical bonding or air bonding for CTP touch(Capative touch panel) and LCD screen.

In summary, choosing Optical bonding or Air bonding mainly depends on the positioning and needs of the product. For devices that pursue the ultimate visual experience and high reliability, full fit is a better choice. For applications that are cost-sensitive or do not require excessive display effects (such as some entry-level equipment or specific industrial equipment), frame stickers are a more cost-effective solution.

Copyright © 2017 Guangdong Shengfeng Technology Co., Ltd. All Rights Reserved.Sitemap | Blog | Xml | Privacy Policy  Network Supported

Network Supported